A version of this post 'Cloud ERPs - The Missing Link in Manufacturing's Evolution' first appeared on the Modern Manufacturing Expo website

There's a lot of hype around the future of manufacturing, at the moment. Terms like 'digital transformation' and 'Industry 4.0' are becoming increasingly popular, but often mislead businesses on how to stay relevant.

Manufacturing has experienced an almost constant state of turbulence for more than a decade and keeping up to date with today's customer needs requires completely different processes (and technology) than in the past.

But what should manufacturers prioritise? Which technologies will help them to achieve these goals? and how can they avoid over-investing in expensive technologies that won't bring real ROI?

- The state of Australian manufacturing

- The journey to Industry 4.0

- The solution to manufacturing's biggest challenges

- How SGESCO-MAX adapted to change with Wiise ERP

- What to look for in a manufacturing ERP

- Time to modernise your manufacturing business

1. The state of Australian manufacturing

Industry 4.0 refers to the so called 'Fourth Industrial Revolution' (the first occurring at the end of the 18th Century, with the emergency of factories and mechanisation, the second in the early 20th Century with mass production, and the third in the 1970s with the introduction of computer technology).

While smart factories certainly offer manufacturers exciting opportunities, the reality is that these technologies present a huge upfront investment – unaffordable for most smaller and mid-sized organisations. This might be the Fourth Industrial Revolution – but it's also a time when running a profitable manufacturing business is increasingly difficult.

In recent years, the industry has faced a series of significant challenges, including:

- Shrinking profit margins – everything is quickly becoming more expensive. Global shipping costs have blown out almost ten-fold in the past year alone – and raw materials, packaging and construction items are scarce.

- Increased regulations – manufacturers are under the spotlight more than ever before, for everything from emissions, tax and payroll transparency to diversity and inclusion.

- Demand variability – seasonality has always been a challenge in managing supply, but today’s customers are becoming ‘paradoxical’ in their buying choices – a nightmare for forecasting demand and production levels.

- Access to skills – most industries are battling a skills crisis – but in manufacturing, where Industry 4.0 has led to an influx of sophisticated technology, the sector is struggling to find staff with the skills to capitalise on these investments.

- Outdated technology – holding onto legacy technology for too long has finally caught up with many manufacturers. The result? Lack of integrations between systems, inadequate data frameworks and slow processes – all of which directly impacts growth and resilience.

2. The journey to Industry 4.0

For most growing manufacturers, the priority needs to be building resilience into business processes and implementing modern systems that will enable the business to grow and scale. Get your business running smoothly, in its current state, before attempting to invest in expensive high-tech solutions or complex machinery. Missing deliveries, running out of the right components to complete customer orders – or being unable to forecast just how many orders your teams can take on in the first place – are all signs that your business has outgrown its old software and is ready to advance to a cloud ERP.

3. The solution to manufacturing's biggest challenges

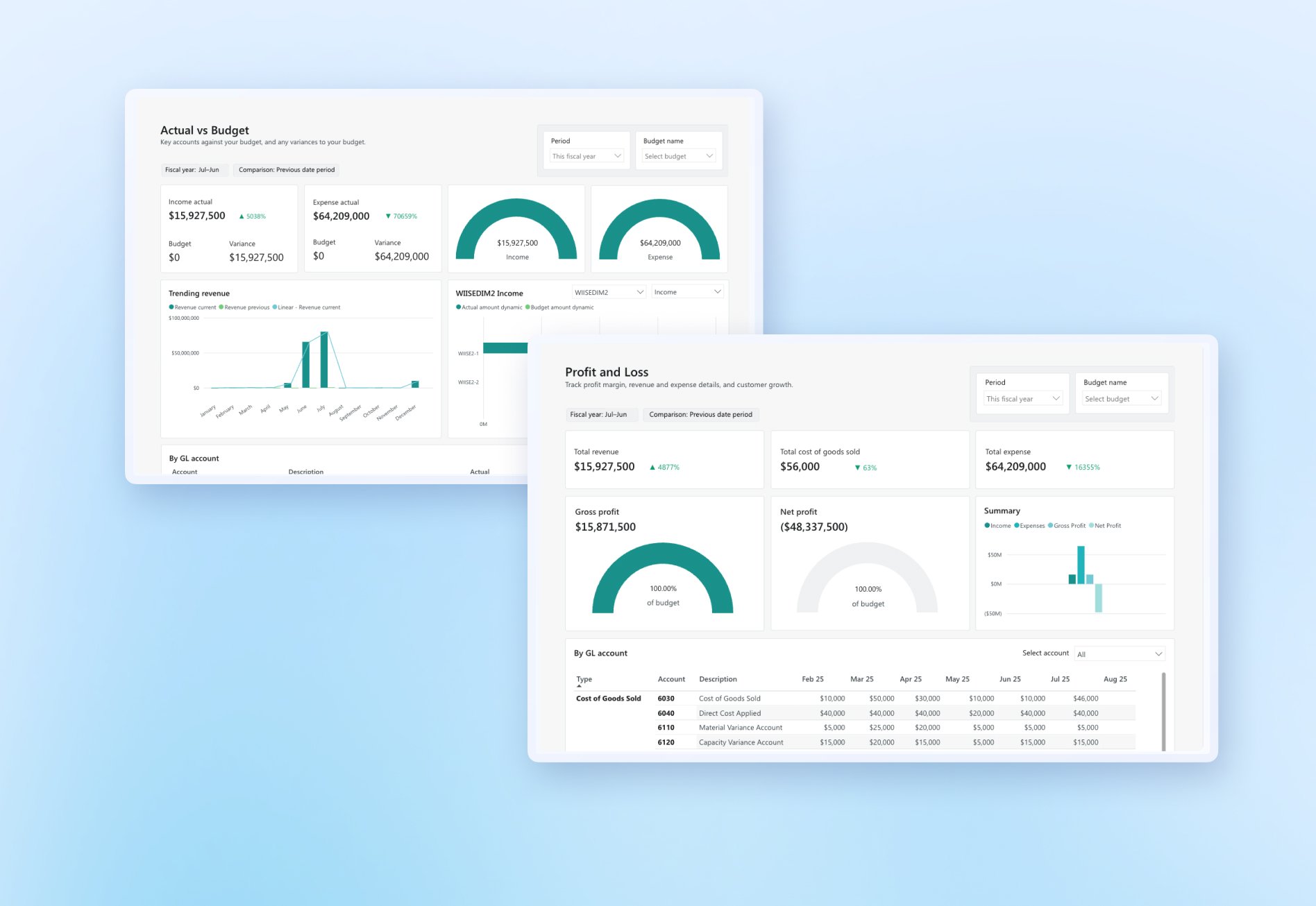

A modern, cloud-based ERP gathers transaction information from every corner of the business, presenting it where and when you need it – in a format that enables you to understand it and make better decisions with it.

While moving to a new ERP is a major undertaking for any business, it has the potential to solve most of a manufacturing business’s biggest challenges. In particular, an ERP can deliver:

- Data-driven decision-making, through AI_powered predictions and business insights.

- Increased efficiency across all operations and processes, through AI and automation.

- Flexible working, with cloud-based solutions that can be accessed any time, anywhere, via any device.

- Scaleable operations, with the ability to handle more customer transactions and complex order tracking.

But don’t just take our word for it. See how Queensland based manufacturer, SGESCO-MAX achieved all of the above, by implementing Wiise.

4. How SGESCO-MAX adapted to change with Wiise ERP

In 2020, Scott McPherson joined SGESCO-MAX – vehicle safety and monitoring solutions company, set-up by his father, in 1962.

Scott saw a lot of opportunity to grow the company, including pivoting from installing its safety products, to manufacturing them. But it was clear none of this would be possible without a serious overhaul of its business software.

Scott’s father had invested in a cutting-edge Wang computer system in the mid-1980’s – but, almost 40 years on, the ‘green screen’ system was officially holding the business back.

“The system just wasn’t built to handle manufacturing. We couldn’t manage assembly orders and had no data to help us plan for capacity – to tell us how many jobs we could handle or how much money we could make.”

Scott McPherson, SGESCO-MAX

Within a year of implementing Wiise ERP, Scott and his teams started reaping the benefits:

- Huge time-savings – faster processes saved staff across the business up to 2,500 hours a year.

- Real-time capacity planning – instant, detailed reporting enabling Scott to plan utilisation, forecasting and profitability on a per-job basis.

- Key manufacturing functionality – including managing the company’s BOM, assemblies and sub-assemblies.

- Native integrations – including the Shopify connector, enabling Scott to launch a new online store and Microsoft integrations, linking data directly from Dynamics CRM and Power BI to Wiise reporting tools.

Scott’s verdict?

“We could not have achieved everything that we have, in such a short period of time without Wiise. The investment has been absolutely critical to the survival and scalability of our business.”

Scott McPherson, SGESCO-MAX

5. What to look for in a manufacturing ERP

Like most industries, manufacturing has its own unique requirements – and industry-specific functionality should be a priority when researching which ERP system is best for your business.

Wiise ERP offers an array of essential tools designed to help manufacturers build resilience and grow their businesses faster:

- See total manufacturing costs – dimensional reporting enables you break down materials, machine time, labour and landed costs, to see your true profit margins. Wiise has built in functionality like landed costing, you can see the true cost of your raw materials and understand your cost of production accurately.

- Version management control – record changes and test new designs under development, enabling you to track and manage production more accurately.

- Capacity planning – see detailed information on resource and component availability, manage teams and utilisation with production calendars.

- Multi-level bills of materials – define material design and cut down on time and admin for your teams.

- Predict supply and demand – with AI-powered insights and your sales, production, purchasing, forecasting and operations fully integrated, Wiise lets you see (and manage) your end-to-end processes.

6. Time to modernise your manufacturing business

A lot has changed – and, with tighter regulations and increased costs on the horizon, now is a great time for Australian manufacturers to build resilience into their businesses and gain a competitive edge.

Ready to learn more?

Book a demo call with one of our friendly team members.