Leveraging Industry 4.0 tech requires solid cloud foundations

The newest wave of technologies which includes the Internet of Things (IoT), cloud computing, AI and machine learning, 3D printing and robotic process automation — collectively referred to as Industry 4.0 technologies — is dramatically changing the way manufacturers produce and distribute their products. One only needs to look to the range of exhibitors at the Modern Manufacturing Expo and key themes of the Expert Arena seminars to understand the magnitude of this change.

But between innovations such as smart sensors and advanced embedded systems, manufacturers today can capture more data from the factory floor than ever before. To make sense of the enormous amounts of raw data that modern technologies can help capture, manufacturers require equally powerful cloud computing and data integration capabilities.

This is why investing in core cloud and SaaS-based applications such as enterprise resource planning (ERP) is the first logical step for manufacturers looking to leverage Industry 4.0 technologies for growth.

Scalable cloud ERP solutions have the ability to not only combine the data generated by everything from IoT sensors to advanced programmable logic controllers (PLCs) to create highly granular production floor data but go a step further by allowing manufacturers to overlay that information on top of broader operational and financial data to get richly detailed business-wide insights.

Simply put, the end-to-end visibility offered by modern cloud ERP solutions enables manufacturers to do more with technology by:

- Being more analytical with decision-making

- Being more responsive to market changes

- Being more responsive to customer needs

- Mitigating supply chain risks at an early stage

- Optimising for efficiency and increasing productivity

The current needs of Australian manufacturers

As an award-winning ERP, we work with manufacturing businesses all over Australia and this is what we’ve learned about your expectations from cloud manufacturing software.

Manufacturing has evolved from being product-centric to customer-centric and manufacturers are urgently seeking better synchronisation between their CRM and supply chain management systems. They need to be able to see what customers are ordering, how much inventory they have on hand, and which suppliers have been most reliable — in one place.

They also seek strong financial management capabilities as growth and recovery become top priorities in a post-pandemic world. Accounting software like Xero can only handle up to 1,000 sales invoices and purchase orders and just 2,000 bank transactions every month. Exceeding this limit can slow the system down, which can be frustrating for growing businesses. Given the typically low margins in manufacturing, senior managers and business owners can no longer afford to make pricing decisions based on rough estimates or inaccurate data in spreadsheets that may not have been kept up to date.

They need the ability to be agile in a volatile market, respond faster to disruptions, and better serve the needs of customers – be it around custom manufacturing or achieving lot-size one production capabilities.

While achieving greater consistency and quality, reducing lead times, simplifying production, reducing handling, and automating workflows are high priorities on the operations side of things, equally important is the security of the network carrying information between key business functions, stakeholders, and systems. Manufacturers today are demanding systems that can guarantee near-zero downtime.

These aren’t just things we hear from our manufacturing customers, it’s what drives us as we continue building on the manufacturing capabilities and integrations in Wiise.

3 things to consider before going ERP shopping

If scaling your manufacturing operations is your priority right now, start by investing in a cloud-based ERP. Don’t just think NetSuite or SAP – look for a cloud manufacturing solution that’s right for your current needs but can just as easily scale with you as you grow. Look for flexible packages and get to know the people behind the tech. Importantly, make sure your next cloud manufacturing software offers the following.

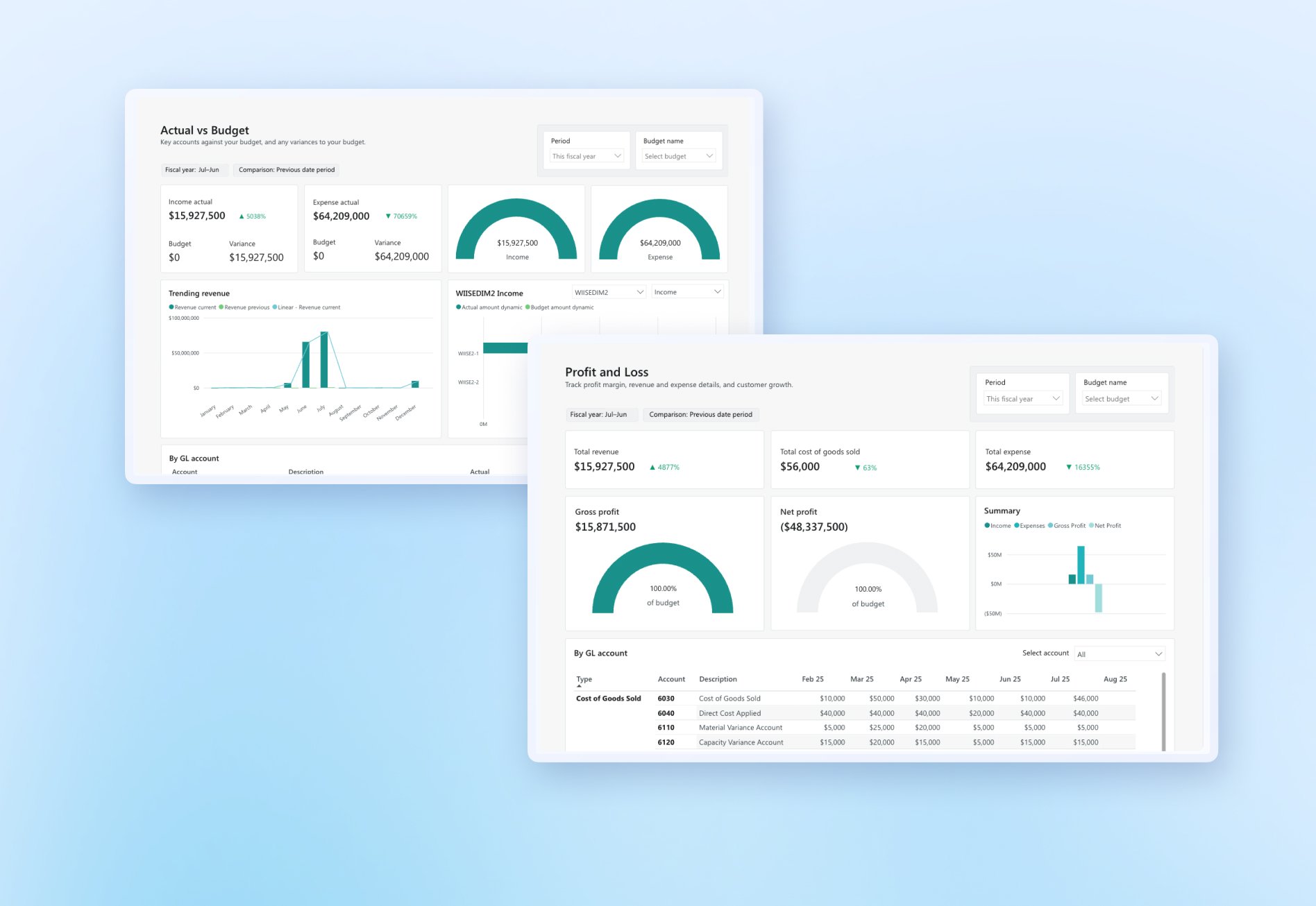

Robust data-analysis capabilities

From web-enabled tools offering real-time visibility of your manufacturing assets to tools that perform predictive maintenance to minimise equipment downtime, before investing in IoT, robotics or other advanced technologies, think about how you’ll analyse the vast amounts of raw data generated by them and where you’ll store it. Choosing a cloud ERP system with powerful built-in analytics can help you make the most of your technology investments.

The same cloud ERP system will also house other business data including your ecosystem of suppliers and distributors, your resources (both people and equipment), sales, inventory, warehousing, and payroll, giving you the ability to be more strategic when making production decisions, setting margins, and allocating resources.

Scalability and cost-effectiveness

Not only does a cloud-based ERP solution make both storing and analysing vast amounts of data more efficient, but it’s also a much more cost-effective option for small and medium-sized manufacturers when compared to on-premises ERP systems that attract annual maintenance fees and ongoing IT costs.

Enterprise-grade ERP solutions such as NetSuite and SAP often need to be heavily customised to suit Australian banking, tax, and business requirements.

Choosing a cloud ERP like Wiise that’s designed in Australia for Australian businesses means you won’t have to budget for costly customisations. Features like industry-specific Chart of Accounts, landed costing, unlimited transactions, Single Touch Payroll with timesheets, multi-currency capabilities and built-in data analytics are available out of the box with Wiise. Native integration with Microsoft makes for even more exciting possibilities such as Power BI reporting or the ability to raise purchase orders straight from Outlook. Given the current economic climate, making your investment go further is crucial.

Advanced cybersecurity

The importance of cybersecurity in manufacturing isn’t often discussed. In May 2021, the world’s largest meat processing company, JBS Foods, fell victim to a cyberattack that targeted the company’s information systems, shutting down production in its factories around the world, including in Australia. Incidents such as these can create logistical problems up and down the supply chain and put enormous hardships on operations teams.

Rather than being an afterthought or an ‘add-on’, cybersecurity needs to be hard baked into a modern manufacturer’s technology strategy. Choosing business software with strong cybersecurity capabilities is key to safeguarding your business.

Look for a cloud ERP solution that can ensure that your data is backed up safely to secure data centres located in Australia and is certified against international security standards.

Supply chain integration capabilities

A transparent supply chain that is fully integrated across the business is the ultimate differentiator in modern manufacturing — emphasis on transparent and fully integrated.

Having full visibility over the supply chain allows manufacturers to better control the efficiency of their operations — from sourcing raw materials to delivering finished products. This can positively impact both staff morale as well as customer experience.

Using a cloud ERP system to integrate the supply chain across operations can unlock even more benefits that range from being able to better schedule deliveries by sharing production data with suppliers to rerouting deliveries when production is disrupted or logistics data and predictive shipping to send finished goods to customers just-in-time.

The last word on modern manufacturing

Successfully transitioning to state-of-the-art manufacturing requires seamless integration between engineering, production, supply chain, sales, and distribution channels. Cloud and SaaS-based core applications such as ERP systems are built to do just that. Manufacturers need to look for scalable ERP solutions that are designed with Australian business requirements in mind and deliver greater return on investment.

Whether discrete or process manufacturing, oil and gas, mining, or food and beverage, the right cloud ERP solution can help a manufacturing business realise value faster on IoT and other Industry 4.0 technologies while being more resilient to disruptions and delivering a more consistent customer experience across the board.