Tracking stock by location. Getting shipments on time and orders out the door. There are many priorities when running a distribution business.

Here are four critical priorities you need to consider in FY23.

1. Challenges facing Australian distributors

COVID created the perfect storm for the supply chain. Disruption to global trade routes, huge changes in buyer behaviour, volatility and uncertainty, have created chaos that is still a long way from being resolved.

Businesses of all sizes are affected. But for small to medium size organisations, with tighter margins and fewer resources, the current situation is particularly challenging. Particularly when businesses aren’t armed with the right tools and data to help them cope with demand spikes and rapidly scale operations. Disconnected and manual processes, combine with a lack of real-time data, make it very hard to plan and be agile.

As KPMG observes, businesses who want to survive and flourish in the challenging global market must review exactly how their resources are being used and focus on building efficiency into every process: "organisations must consider all of the activities that are necessary, but don’t add great value. They need to look at ways to minimise the amount of time and resources spent on these – making them as lean as possible."

2. Struggling with older systems

One of our customers runs a family-owned hardware distribution business based in Victoria. They recently experienced an influx in sales due to higher demand, with the business growing by 30%. They were using a very basic accounting system and didn’t have a CRM platform in place for their sales team. They quickly found themselves unable to process orders fast enough as their accounting software could only handle a limited number of transactions. The operations and sales team were spending more time updating spreadsheets than processing orders and dispatches.

Many Australian organisations are in a similar situation. They have been forced to digitise operations and processes nearly overnight, but are stuck with legacy solutions that cannot cope with increased volume nor provide the real-time data required for today’s distribution chains to operate efficiently. What distributors need is a single, easy-to-use system that can scale, store sales, inventory, orders and shipping data in one place and automate manual admin, such as updating spreadsheets.

3. Data, automation needed for a competitive edge

Speed is everything in the current market. Businesses must be competitive to survive. Customers expect more, which means being able to offer the best products at the best price. If you don’t have a handle on your cost of goods or it takes you too long to determine what your true cost of sale should be, you’ll be left behind.

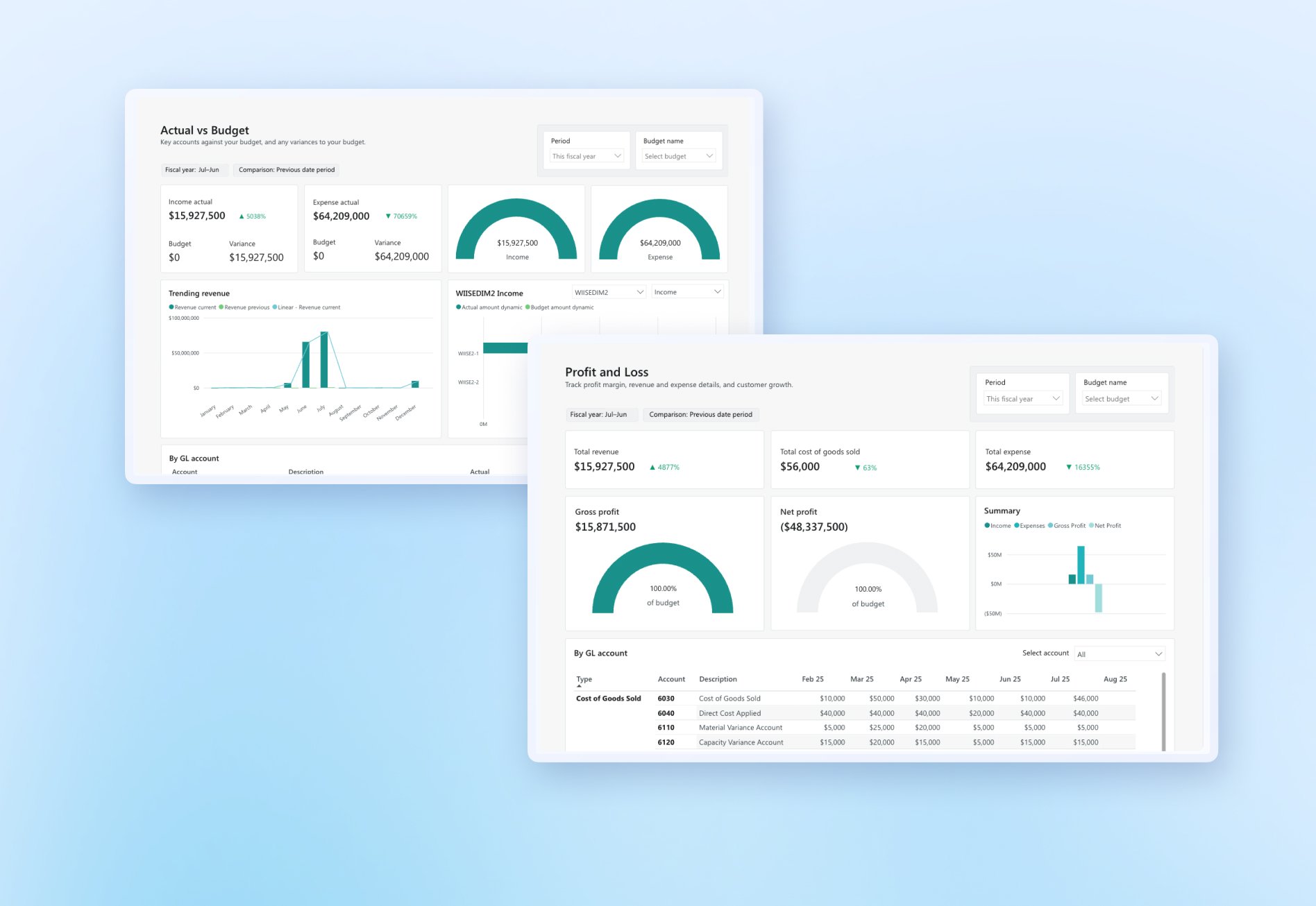

To do this, businesses need data. Without accurate, timely and relevant information, it is impossible to make confident business performance decisions and drive operational efficiencies.

Some companies are reluctant to change existing processes, but this puts them at a disadvantage in a competitive environment. KPMG notes that smaller businesses in particular are still writing cheques, manually inputting invoices and process expenses manually and individually: "Labour is a principal driver of cost in Australia and this investment is not being utilised effectively if employees are focusing their time on low value, low-level transaction processing."

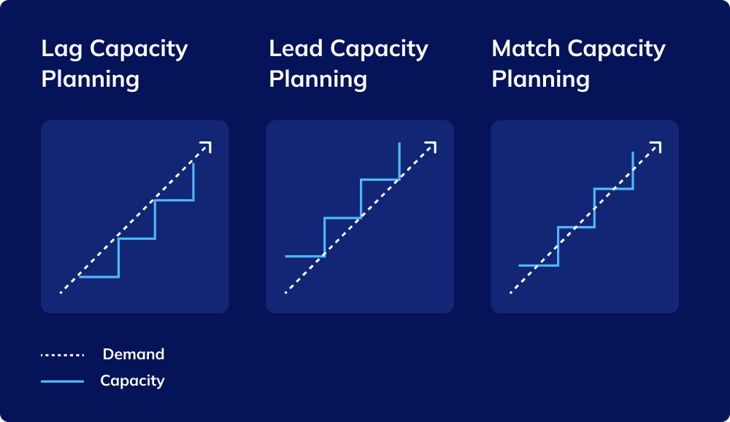

4. Taking a staged approach

Moving to a future-fit, cloud-based system doesn’t have to be done all at once. A staged approach is advisable, starting with finances and then inventory before moving to basic warehousing and eventually advanced warehousing.

Finding the right solution has transformed the Victorian hardware distribution business. The sales team can process orders directly from Outlook, enabling the business to get revenue in faster and continue on its growth trajectory without limitations. Stock levels are improved, with automatic levels set for reordering.

Pricing is also much easier with landed costs. With every cost from shipping to port duty and clearance charges accounted for, they can price their products much more competitively and maximise revenue.

Customers are also happier. There are no more delays, and the team is getting orders out in under a few hours.

In the current volatile environment, where constant change is the "new normal", having efficient operations and the right technology enables people to focus on the core business and think strategically. This means that rather than being taken by surprise by market shifts and scrambling to catch up, shifts can instead be turned into an opportunity.

Ready to learn more?

Book a demo call with one of our friendly team members.