This article first appeared here in Industry Update Manufacturing Magazine.

9/12/20, Guest Editorial, Industry News. Jonathan Attia, Managing Director, Wiise.

Supply chains have seen immense disruption during the COVID-19 pandemic. Many have been more critical than ever before, delivering vital goods and services to people in lockdown, but have faced obstacles ranging from restricted flight and transport options to staff shortages.

A strong economy needs resilient supply chains that are prepared for unexpected risk events and can handle disturbance. But according to a recent Gartner survey, only 21% of respondents claimed to have a highly resilient network.

While the pandemic might seem like a completely unpredictable, "black swan" event, a truly resilient supply chain will have strategy and systems in place to cope with extreme disruption. Such a strategy is based on three key pillars.

Pillar 1 - Flexibility

And as remote work is becoming more common, along with official crisis responses such as lockdowns, using cloud-based technology is critical to ensure all systems and data can be available anywhere, at any time. While many supply chain businesses needed to have warehouse staff on the floor, finance and customer service team members could work from home.

For those manufacturing businesses that were still using legacy systems such as on-premise ERP, this was difficult. Whereas those that were already leveraging cloud technology could easily send some staff home while keeping those with labour intensive roles on the floor.

Until recently, supply chain businesses have been a little slow to go digital. But during the pandemic, 49% of SMBs changed the way they delivered products and services to customers.

Smart supply chain businesses are already investing in technology to reach customers online, and focusing on creating a great online ordering experience. This flexibility is helping supply chains build resilience. If you’re able to change your business strategy or the way you sell, you can easily adapt and keep moving. Steps to take include:

- Look at what processes in your supply chain can be automated or streamlined

- Think of ways you can create a digital delivery experience, without the need for person-to-person contact

- Look at the feasibility of selling your product online, direct to the consumer

- Move suitable business functions to a self-serve model

- Adopt standardised practices, using interchangeable parts and production facilities, and cross-train employees, so you can instantly reallocate resources

- Find the right software to help you manage your supply chain, capture your data, and respond to your customer

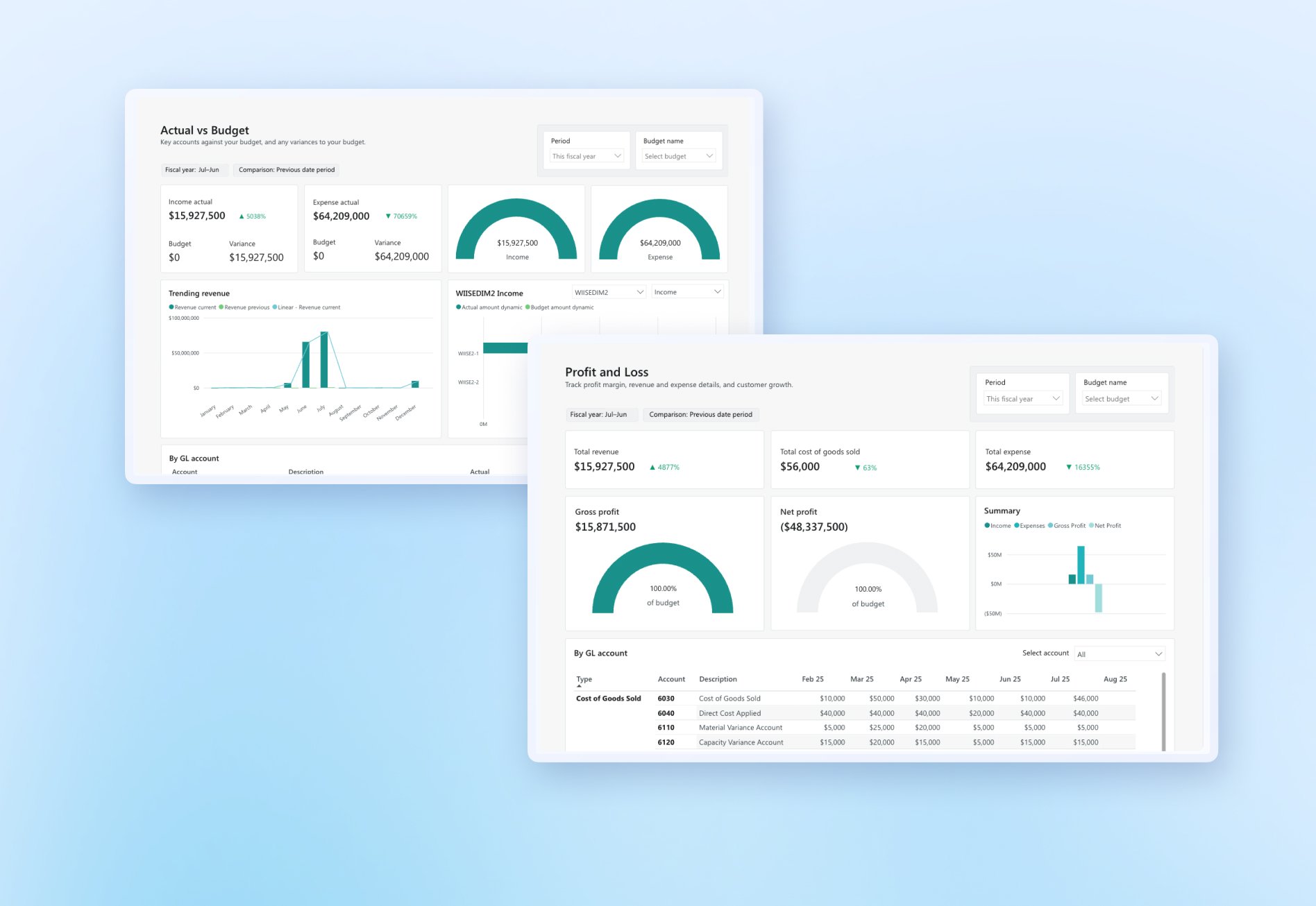

If you’re running your business from software in the cloud, using a digital ERP system, anyone in your business can access their dashboard from anywhere to see what's happening. They can see where things need to change and where bottlenecks are occurring.

Pillar 2 - Ability to go lean

What COVID has shown businesses today is where their costs are going. Manufacturing and supply chain businesses had to have a good hard look at their expenses to determine where they could save costs. This move was deemed crucial for their survival, and many staff had to be let go.

This leaner approach will remain post-COVID. The supply chain of the future will be leaner than ever before. Theoretically, resilience can be built by creating redundancies: extra inventory, extra capacity, extra staff, etc. But this is a very expensive measure. While it means you can "switch up" whenever demand surges, the spare capacity lying around the rest of the time is costly and wasteful - at a time when budgets are under immense pressure.

Instead, lean strategies should be used to create more efficient supply chains. Supply chain businesses should review expenses and make savings where possible. To do this, they’ll need to benchmark themselves and measure performance against costs. You can’t see if productivity is increasing or decreasing otherwise.

To build resilience, it’s important for manufacturers, distributors and those managing inventory to understand their true cost of sale. With over 68% of Australian businesses relying on international trade and the impact of COVID, there was a flow on effect. Air freight sky rocketed due to less flights, the cost of imported goods increased tremendously and as well shipping fees and taxes and suddenly, businesses that were selling their product at $20 were no longer making a profit.

Technology, specifically cloud ERP, can help you automatically re-calibrate the cost of sale based on all of the shipping fees and goods to ensure you’re always making a profit when you process your purchase orders and get your inventory out the door.

As you streamline your performance you need to keep iterating, and you need good data for this. The right cloud-based ERP will help you get good visibility and insights, including financial KPIs such as:

- Supply chain management cost

- Cash-to-cash cycle time

- Warehouse storage costs

- Transport costs

Pillar 3 - Contingencies

Resilient supply chains need to be prepared for rapid upscaling/downscaling of operations, including finding new suppliers or extra suppliers. "Multisourcing" and "nearsourcing" are increasing. But predicting and planning for these changes is a challenge. What data can you use to forecast changing demand?

A lot of data is based on trends: insights based on historic performance year-by-year. COVID-19 has wiped out the relevance of old data, as former systems and considerations no longer apply. To make sensible contingency plans, supply chain businesses need new, high quality, real-time data. This data can’t be extracted quickly enough from manual processes to be useful. By the time the data is dug up and analysed, it’s outdated. By going digital, the information is much more accurate, immediate and relevant, and can be used to generate better insights.

While investing in new digital technology might seem risky when budgets are constrained, the ROI for many smaller businesses can be rapid. Many of the new supply chain planning capabilities or applications can be used as a service: they can be leased monthly and turned on or off as required. This offers better flexibility and affordability. And from a managed services perspective, it creates new opportunities and gives access to high-end capability without the cost.

The same goes for contingencies when it comes to vendors. You need to be able to hold on to your top vendors but also have a contingency plan in place, so you can easily pivot if stock runs out or you can’t get your item delivered in time.

Supply chain roles are changing dramatically. There’s a move towards hybrids; people with one foot in the traditional operations and logistics domain, and the other in technology. The most successful and resilient supply chains are those which are responsive to changing customer requirements in the most efficient, cost-effective way possible.

Jonathan Attia,

Managing Director, Wiise.

This article first appeared here in Industry Update Manufacturing Magazine.